Our Products

Linear Feeder

Linear feeders are designed to transport and position parts from the feeder bowl to assembly lines. They are four type of Linear to transfer the components to Pick Up Place Position.

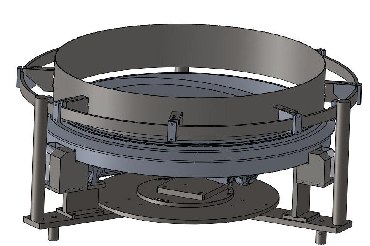

1. Vibratory In Line Feeder

Vibratory inline feeder systems are paired with vibratory Bowl feeders to move parts from the bowl to the pick point while maintaining part orientation. They are ideal for small parts, durable, and are low friction. Vibratory inline feeder systems are Start with 150mm to until 3 meter.

Vibratory inline feeder systems are paired with vibratory Bowl feeders to move parts from the bowl to the pick point while maintaining part orientation. They are ideal for small parts, durable, and are low friction. Vibratory inline feeder systems are Start with 150mm to until 3 meter.

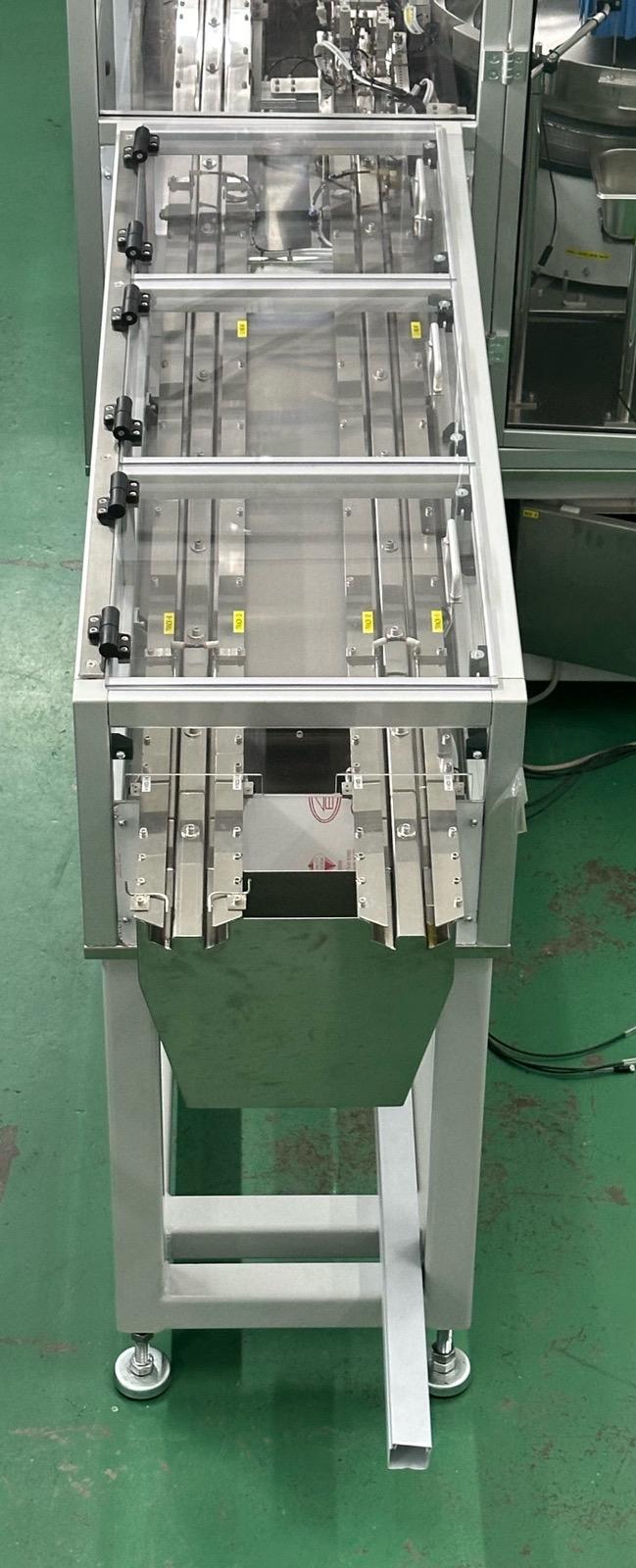

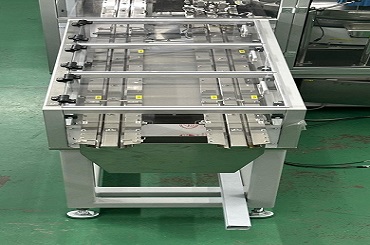

2. Conveyor Linear Feeder

Conveyor linear feeder systems are normally paired with centrifugal bowl feeders. They are capable of high accumulation and operate quietly at high speeds. Conveyor linear feeder systems normally have a control system that increases their efficiency.

Conveyor linear feeder systems are normally paired with centrifugal bowl feeders. They are capable of high accumulation and operate quietly at high speeds. Conveyor linear feeder systems normally have a control system that increases their efficiency.

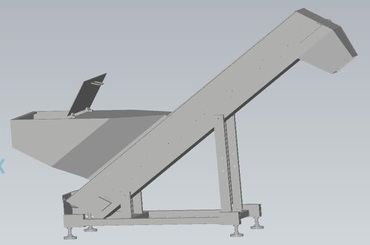

3. Air Track Linear System

Airveyor inline feeder systems are an ideal solution when elevation change is required. They work at very high speeds but are gentle on parts. Airveyor inline feeder systems use blowers to move parts and are the perfect solution for rapidly moving lightweight parts.

Airveyor inline feeder systems are an ideal solution when elevation change is required. They work at very high speeds but are gentle on parts. Airveyor inline feeder systems use blowers to move parts and are the perfect solution for rapidly moving lightweight parts.

4. Gravity Track Linear System

The force that guides a gravity track linear feeder system is gravity without any form of mechanical energy. They are the least expensive of the linear feeding systems, produce less noise, and do not require any form of consumable parts or maintenance. Gravity track linear feeder systems have to be located at a effective, higher angle track to be elevation for the downward.

The force that guides a gravity track linear feeder system is gravity without any form of mechanical energy. They are the least expensive of the linear feeding systems, produce less noise, and do not require any form of consumable parts or maintenance. Gravity track linear feeder systems have to be located at a effective, higher angle track to be elevation for the downward.